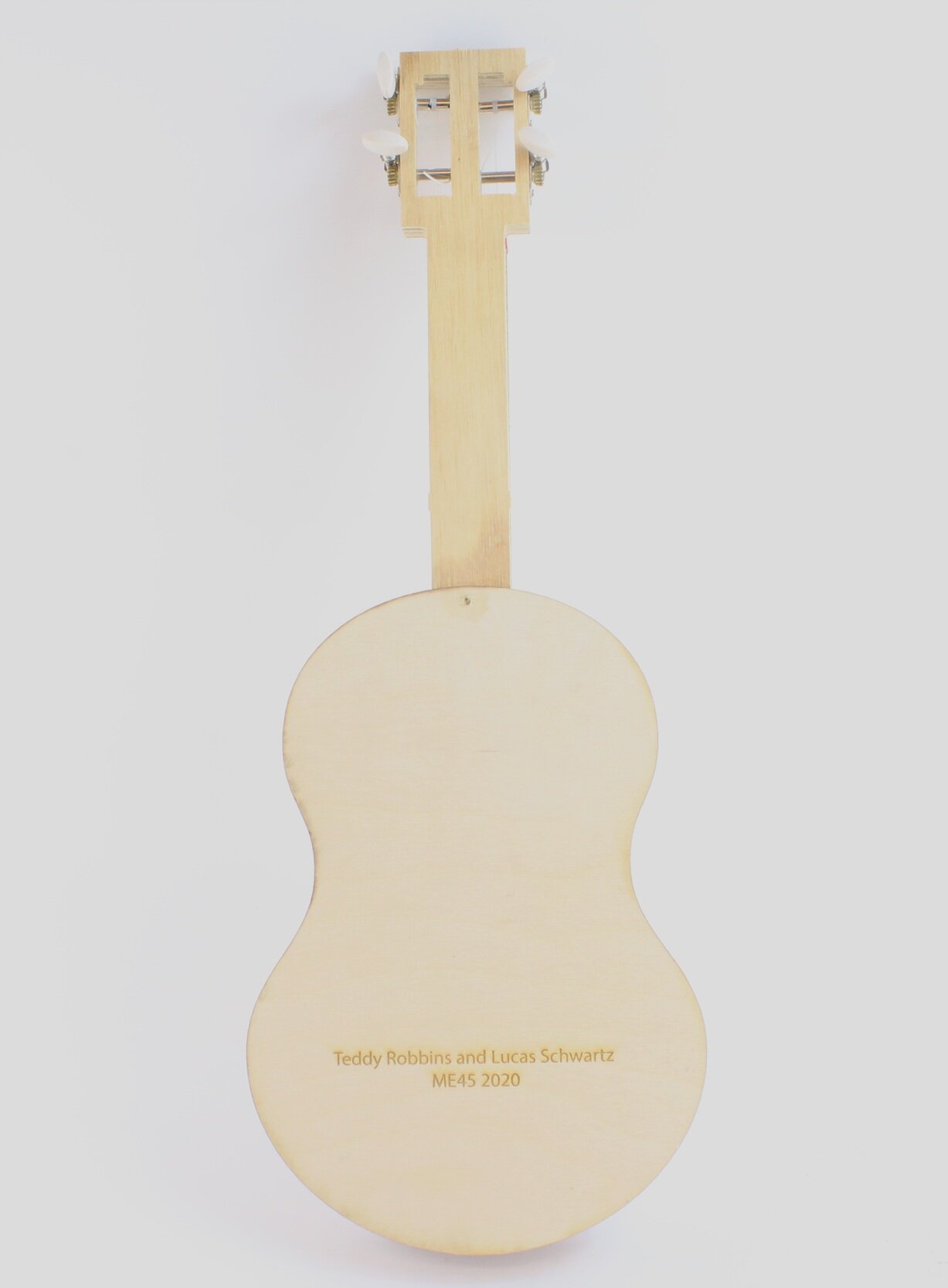

Ukulele

Project Description

For my first project in my Music Instrument Design & Manufacture class I was tasked with building a Ukulele along with a partner. Most of the neck and fret board had been pre-designed and partially built by our professor, but the design of the resonating cavity was up to us to create.

I decided to design a resonating cavity in Solidworks that would mimic a ukulele shape using mirrored splines. Fine tuning the splines to match the characteristic shape of a ukulele was more difficult than I had anticipated, but I feel that I did a good job. Two pieces of laser-cut wood were used for the top and the bottom of the resonating cavity and the middle was carved out of red oak using a CNC. The outside of the red oak middle was manually carved away on a band saw using a pattern etched by the CNC as a guide. The three pieces were glued together and screwed into the neck to complete the assembly.