Teardown Project

Project Description

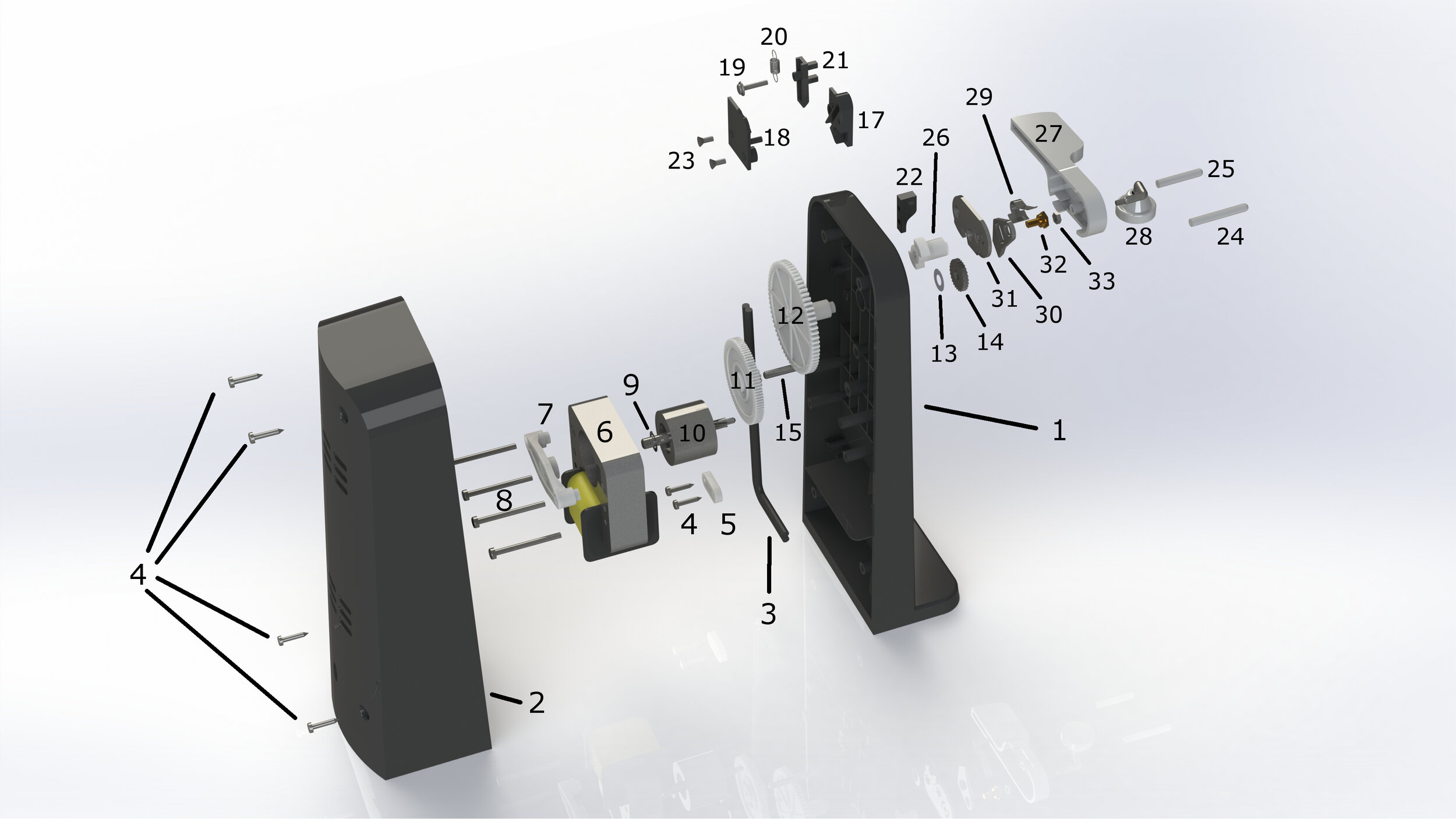

In my mechanical engineering design class, along with a team of 4 other students, I was tasked with tearing down a Cuisinart Can Opener and producing an extensive report on its design, including a complete recreation of the product in SolidWorks.

In the team of 5 students, my main responsibilities included reverse-engineering the complex shell of the model, and CADing multiple other parts in the 30+ part assembly. I took dimensions from the real-life parts using digital calipers and a tape measure, and then sketched the parts first on paper and then in SolidWorks. Finally, I received all of the other parts that the rest of the team had designed, and I mated every sub-assembly to produce a functional assembled model of the can opener. I added materials to the parts and created cutaway and exploded views via a PhotoView360 render.

I also contributed to the writing and production of the final teardown report, displayed below.